Industrial Automation

We deliver comprehensive electrical and automation solutions—from design and sizing to installation, testing, and commissioning.

Our Services cover HT/LT systems, power studies, SCADA/PLC integration, and regulatory compliance. With expertise across transformers, panels, motors, and cabling, we ensure reliable, safe, and efficient operations. We also offer vendor inspections, site supervision, and specialized audits to maintain system integrity and performance.

Core Services & Engineering Expertise

Specialized Engineering Solutions

Instrumentation & Electrical

Greenfield/Brownfield design, power system studies, cable routing, earthing, lighting, and BOQs.

Factory Testing

Panel, PLC, transformer, and motor testing per QAP with complete documentation.

On-Site Execution

Installation supervision, system testing, calibration, and safety audits.

Automation & Control

PLC/DCS/SCADA design, historian setup, protocols, FAT/SAT, and commissioning.

Detailed Design

Load lists, cable schedules, MCC/IMCC, protection coordination, GA drawings, and BOMs.

System Integration

CCTV, ACS, LAN, voice/video systems with heat load calculations and termination plans.

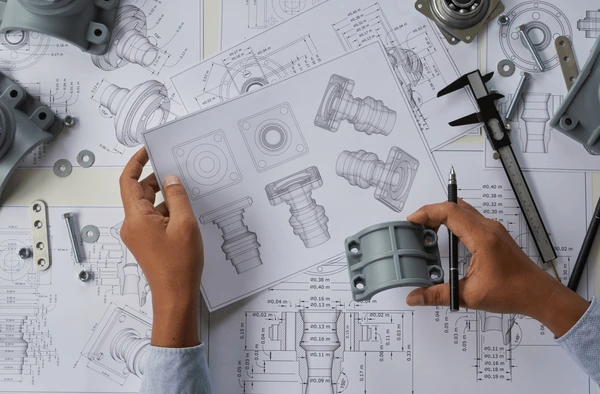

We offer specialized design and drafting services powered by a team of highly skilled professionals proficient in leading industry-standard CAD and engineering platforms.

1. Basic Engineering

– Design Basis Development: Preparation of Design Basis document, Electrical Load List, Overall Single Line Diagrams (SLD).

– Various Sizing Calculations: Transformer, Cables, Earthing System, Lightning Protections.

– Design Basis Development: Preparation of Design Basis document, Electrical Load List, Overall Single Line Diagrams (SLD).

– Various Sizing Calculations: Transformer, Cables, Earthing System, Lightning Protections.

2. Detailed Engineering Equipment’s

– Pre Ordering: Release of specifications for getting the vendor offer, vetting the offers as per the tender requirement, and providing technical clearance for placing the order.

– Post Ordering: Vendor drawing evaluation, getting approval from consultant/client, coordination with vendors, as-built documentation and regulatory approvals.

– Change Management: Delay analysis, scope deviation tracking (Contract vs Actual).

3. Power System Studies

Load Flow Study, Short Circuit Study, Relay Coordination, Transient Study, and Harmonic Analysis.

4. Plant Engineering

Equipment layout, civil cut-outs, cable tray layout, earthing grid and grounding system layout, lighting/illumination, and lightning protection.

5. HT/LT Power Cable Engineering

Cable selection, sizing, scheduling, routing, and BOQ.

6. Erection Material BOQ

Detailed BOQ for steel, cable tray, earthing and lighting system, and erection hardware.

We deliver advanced simulation and analysis services through a dedicated team of CAE experts, helping clients validate, optimize, and enhance their designs before physical prototyping. Our engineers are proficient in industry-leading tools for structural, thermal, dynamic, and crash simulations.

1. Basic Engineering

– Basic Design: Overall configuration & System architecture. Selection Criteria for Field Instruments, P&ID drawing, Basic IO List, UPS Sizing calculation, Selection.

– Design Criteria Control and Instrumentation Cable & Earthing.

2. Detailed Engineering Equipment’s:

– Pre Ordering: Release of specifications for getting the vendor offer, Wetting the Offers as per the tender requirement and Providing Technical clearance for placing the order.

– Post Ordering: Vendor drawing Evaluation, getting approval from consultant/client, Co-ordination with vendors, as built documentation.

– Change Management: Delay analysis, Scope Change (Contract Vs Actual).

3. Plant Engineering:

-IO Panels, LPBS, Control desk Control JB, field instrument location drawing, Interconnection drawings, Block Interlock drawing.

4. C&I Cable Engineering:

– C&I control cable engineering (schedule and Estimation).

Our team has extensive experience in handling a wide range of electrical equipment across voltage levels and industrial applications. We ensure seamless integration, compliance, and operational efficiency across all systems.

1. High Voltage (HV) & Switchyard Equipment:

– Circuit Breakers (CB)

– Current Transformers (CT) & Potential Transformers (PT)

– Isolators

– Control & Relay Panels (CRP)

2. Power & Distribution Transformers

– Power Transformers

– Distribution Transformers (ONAN/AN)

– Converter Transformers

– Lighting Transformers

3. Medium Voltage (MV) Equipment – up to 33kV

– MV Panels, GIS & AIS

– MV Busducts

– Compact Substations

– E-House (Electrical Houses)

– Diesel Generator (DG) Sets

– Battery Banks & Chargers

– Uninterruptible Power Supply (UPS)

4. Low Voltage (LV) Equipment

– Power Control Centres (PCC)

– Motor Control Centres (MCC) & Intelligent MCCs (IMCC)

– Soft Starters & CRPs

– LV Busducts

– Distribution Boards

5. Rotating Machines

– Medium Voltage Motors

– Low Voltage Motors

– Cabling Systems

– HT & LT Power Cables

– Control Cables

– Instrumentation Cables

– Special Application Cables

6. Support & Utility Systems

– Air Conditioning & Ventilation Systems

– Fire Detection & Alarm (FDA) Systems

– CCTV Surveillance & Public Address (PA) Systems

– Nitrogen (N₂) Systems

– Industrial Lighting Fixtures

– Cable Trays

– Earthing Systems

– Distribution Boards & Junction Boxes

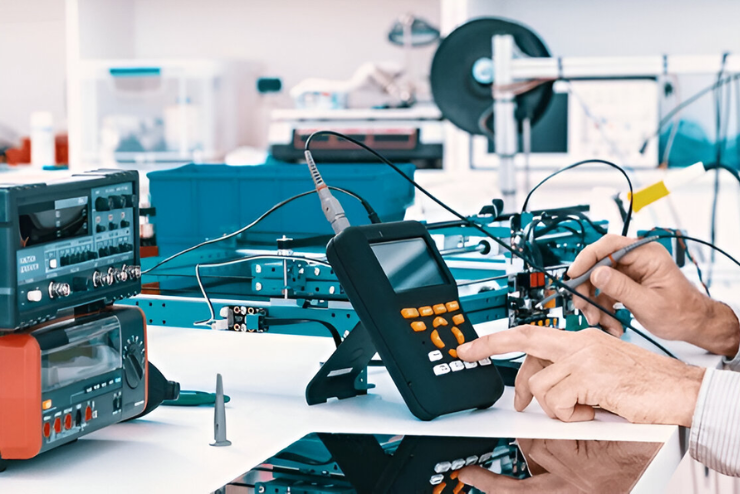

We conduct comprehensive Inspection & Testing at vendor facilities to ensure all equipment meets design specifications, quality standards, and client expectations.

1. Scope of Inspection

– Switchyard Equipment, MV/LT Panels (PCC, MCC, PDB)

– Power, Distribution & Converter Transformers

– CRP Panels, MV/LV Motors, DG Sets, UPS, Bus Ducts

– HT/LT Power, Control, Instrumentation Cables

– Compact Substations (CSS), E-House, Battery Chargers

– N₂ Systems, Automation Panels (PLC & I/O Panels)

2. Inspection Highlights

– Validation of Approved Drawings & Test Instruments

– Review of Bought-out Items with Manufacturer’s TC

– Calibration Verification of Testing Equipment

– Safety Interlock & Power Termination Checks

– Site-Centric Review: Maintenance Clearances & Field Adaptability

– Engineering Change Incorporation (if required)• HVAC & thermal system simulations

• External & internal aerodynamics

• Multiphase flow analysis

• Combustion modelling

• Electronic cooling

• Process equipment optimization.

3. Value-Added Assurance

– Coordinated inspections with Vendor, Customer & Consultant

– Timely inspection scheduling and punch point resolution

– Update of “As-Manufactured” drawings prior to dispatch

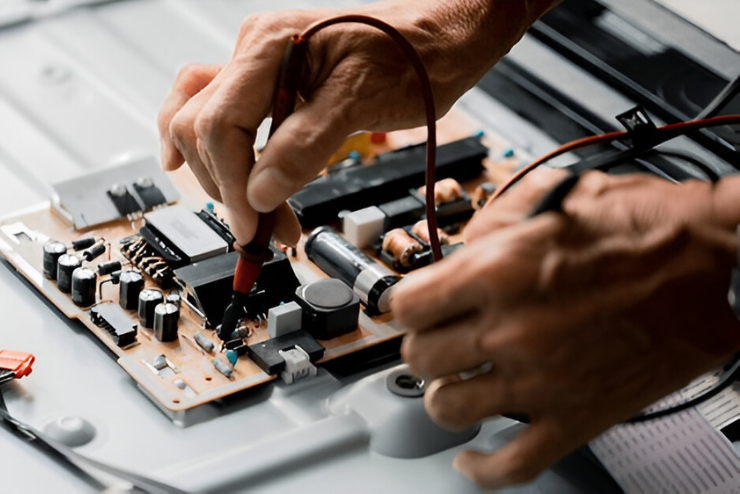

Our experienced and dedicated team provides comprehensive field support for the erection, testing, and commissioning of electrical systems, ensuring safe, efficient, and compliant operations at site.

1. On-Site Services

Supervision of Erection & Installation for:

– Indoor/Outdoor Substations

– Power & Distribution Transformers

– HT/MV Panels, LV Panels (PCC, MCC)

– Control & Relay Panels (CRP)

– Cable Trays & Power/Control Cabling

2. Testing & Commissioning

– Functional testing and commissioning of all electrical equipment

– Relay coordination settings using ETAP for plant safety

– Troubleshooting & technical support for complex power systems

3. Maintenance & Calibration

– Annual maintenance and health checks for substation equipment

– Testing & calibration of meters and protection devices

– Technical recommendations for preventive care or corrective action

4. Specialized Audits

– Power Quality Analysis

– Fire Safety Audits

– Actionable Solutions